Though it sounds like alchemy, D’Arcy Lab combines technologies to engineer cutting-edge microsupercapacitors from rust.

Imagine a battery that charges quickly, retains its capacity to hold charge over many thousands of charging cycles, and can operate efficiently at temperatures up to 140 degrees F. Now imagine this device isn’t a battery at all; it’s a supercapacitor.

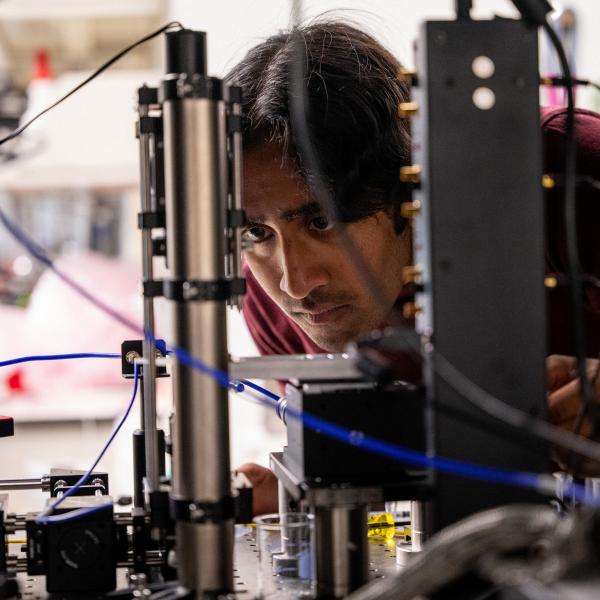

New methods for engineering microsupercapacitors developed by Julio M. D’Arcy, assistant professor in the Department of Chemistry, and collaborators at Washington University’s Institute of Materials Science & Engineering combine conventional microfabrication techniques with cutting-edge polymerization. The team’s microsupercapacitors show exceptional electrical conductivity and energy density, producing the highest such values of any conducting polymer-based microsupercapacitors. The results are published in Advanced Functional Materials.

Though batteries have higher energy densities than capacitors — batteries can supply electricity for longer than capacitors can — capacitors are superior in power density, meaning they can deliver energy very quickly. Supercapacitors are specially designed to store more energy than regular capacitors, making them ideal for applications such as sensors, RFID tags, and microrobots, which all require high-performing miniaturized energy storage.

For their work on microsupercapacitors, D’Arcy’s team combined clean room technology with fume hood technology.

“Typically, what you do in a clean room is processing materials that end up in computers, such as semiconductors,” D’Arcy said, noting that clean room environments are strictly regulated to eliminate dust and other impurities in the air. “In the clean room here on campus, in the Institute of Materials Science & Engineering, they have a lot of really cool instrumentation, including an instrument that allows you to deposit a thin layer of material on a surface. Using this instrument, we deposited films of Fe2O3 down to 20 nanometers – very thin metal oxide films – which we couldn’t do in any other way.”

If Fe2O3 sounds familiar, it should – it’s rust. For D’Arcy and his team, this common material makes an ideal and inexpensive starting point for chemical synthesis.

“Once the rust is deposited, it’s incredibly stable and inert. It can be exposed to the atmosphere with no problem, so then we can walk out of the cleanroom and back into the chemistry lab to our fume hood where we use that layer of metal oxide as a reactant in chemical synthesis,” D’Arcy said.

Converting rust into state-of-the-art conducting polymer-based microsupercapacitors turns out to be remarkably straightforward.

“The easiest way to remove rust from a surface is to add a little bit of acid. That’s what the rust remover you get at the hardware store is. Our conversion works the same way – we add acid and change the iron oxide by liberating an iron atom. That iron atom becomes the reactant for our polymer vapor,” D’Arcy explained. This process is known as rust-assisted vapor-phase polymerization.

“What we discovered, and what’s so exciting about our process, is that the outcome of our chemical reaction is unique. It’s a self-assembly process,” D’Arcy continued. “We’re making nanostructures of a polymer, basically a thin film or carpet of nanopolymer brushes. The soft, semiconducting, organic material deposits on the surface wherever there was rust. That conversion – from the film that we deposited in the cleanroom to nanofiber material – is a direct conversion. No one in the field has been able to make nanostructures without a template at this scale. We do it directly; we’ve developed a synthesis that leads to self-assembly.”

D’Arcy credits first author Yifan Diao, a graduate student in IMSE and D’Arcy Lab, with coming up with the idea to deposit microfilms in the cleanroom. D’Arcy noted, “When we went really small, which is what cleanroom technology allows us to do, we discovered that everything got better. It’s a lot easier to control chemical properties on smaller electrodes, and the results in this case, I would say, were exquisite. The concept of working at the micro scale turned out to be an ideal solution across a lot of cases.”

This project won $50,000 in funding from the Leadership and Entrepreneurial Acceleration Program (LEAP) in fall 2019. The award supports the development of this method of microsupercapacitor fabrication into commercial technology. Already, the team has multiple pending patent applications covering this work and related technologies. The team anticipates future applications in miniaturized devices ranging from biomedical sensors to wearables where cost-effective alternatives to batteries are desired.

D’Arcy also touted the simplicity of the fabrication method compared to other energy storage devices, noting that the synthesis occurs in a single step because it is a self-assembly process. “We found a sweet spot where we can engineer self-assembly and then watch nature happen. Instead of having multiple synthetic steps, we have a single one. The high conductivity, energy density, and nanofiber structure were the result of controlling the interaction between the vapor and the thin film, so they come together just how we want. In this case, it was seamless.”

Looking ahead, the team will continue working to improve energy density to make the microsupercapacitors more competitive with batteries, while at the same time retaining high conductivity and electrochemical stability.

Acknowledgements

The researchers thank Professor Vijay Ramani from the Department of Energy, Environmental & Chemical Engineering for his mentorship during the development of this technology into a successful LEAP entry. They would also like to thank Dr. Raul Gupta and Dr. Huafang Li from the Institute of Materials Science & Engineering for helping with the experiments.